CASE

Life science laboratory

Located in a city area with heavy traffic, a leading Danish university sought to protect their research by improving air quality in their laboratory, while also cutting down on energy cost.

We are provide cleaner air and achieving energy savings through collaboration with our ventilation partner.

The ventilation upgrade at the university laboratory has been meticulously documented. There has been a documented 98% reduction in the admission of ultrafine particles (PM 0.3 µm) into the laboratories. Moreover, measurements show that fan operation decreased from 66% to 41% after installation, which can be directly attributed to the substantial reduction in pressure drop.

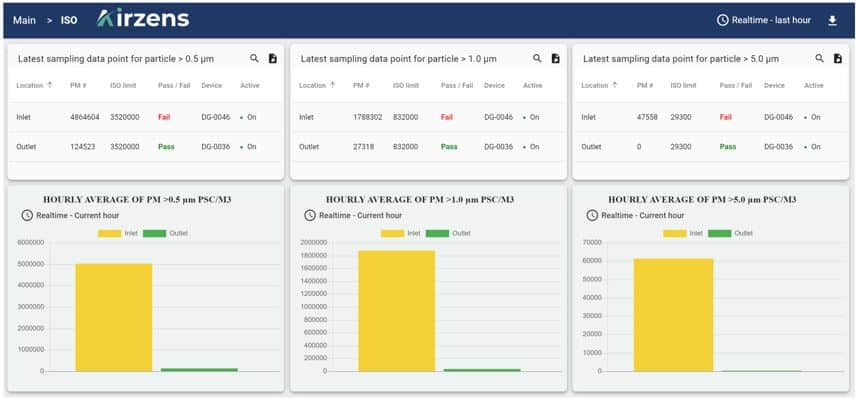

To ensure the accuracy of our results, AeroTrack-calibrated sensor systems were installed both before and after the ESP filter section during the installation of the Airzens filtration system. In line with ISO 8 cleanroom standards, the concentration of airborne particles larger than 0.5 µm per cubic meter of air is strictly controlled.

Control parameters for the university laboratory :

The data unequivocally demonstrates that, following the implementation of the Airzens filtration system, the particle quantity remains within ISO 8 cleanroom standards. Notably, there is a noticeable enhancement in filtration efficiency, particularly in the ultrafine spectrum (PM <2.5).

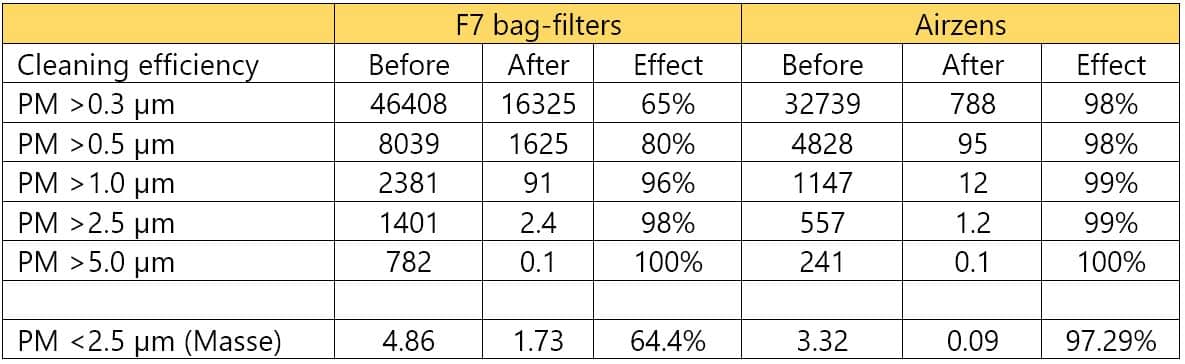

We conducted meticulous measurements of particle counts in the 0.3 to 5.0 µm range, categorized from “PM >0.3 µm” to “PM >5.0 µm.” Additionally, we measured the total particle mass at PM <2.5 µm.

The data below provides a comprehensive overview of the total particle count, both before and after the installation of ESP technology. For PM >0.3 µm (as shown below), a conventional F7 bag filter removes 65% of particles larger than 0.3 µm, whereas an Airzens filter eliminates an impressive 98% of all particles larger than 0.3 µm.