CASE

Novo Nordisk

Novo replaces disposable filters with Airzens to reduce waste, provide cleaner air, and to unlock energy and CO₂ savings.

We are delivering cleaner and co2 savings for Novo Nordisk in partnership with our ventilation partner.

CO₂ & energy reduction:

Novo Nordisk remains unwavering in its commitment to reducing its environmental impact. This dedication encompasses responsible resource management, energy efficiency optimization, waste minimization, and the embrace of sustainable practices, extending even to ventilation upgrades.

As a testament to these efforts, Airzens conducted a six-month pilot installation at Novo Nordisk’s Måløv facility in Denmark. This pilot project focused on CO2 reduction, with energy consumption meticulously measured by an accredited third party, Airgroup.

The installation targeted an office building with an intake air volume of 10,600m3/h and an outlet air volume of 10,500m3/h. In this process, 14 F7 bag filters were replaced with Airzens electronic filters.

Based on a CO₂ _eq of 149 grams/kilowatt-hour, the annual CO2 reduction achieved through the pilot installation amounts to approximately 3,700 kilograms per annum. This reduction also includes the savings accrued from no longer needing to replace bag filters annually.

Considering the Airzens filters’ estimated 20-year lifespan, the cumulative potential for savings over their lifetime is substantial.

Clean air delivery:

In addition to CO₂ reduction, the ventilation upgrade at Novo Nordisk has been meticulously documented to enhance clean air delivery.

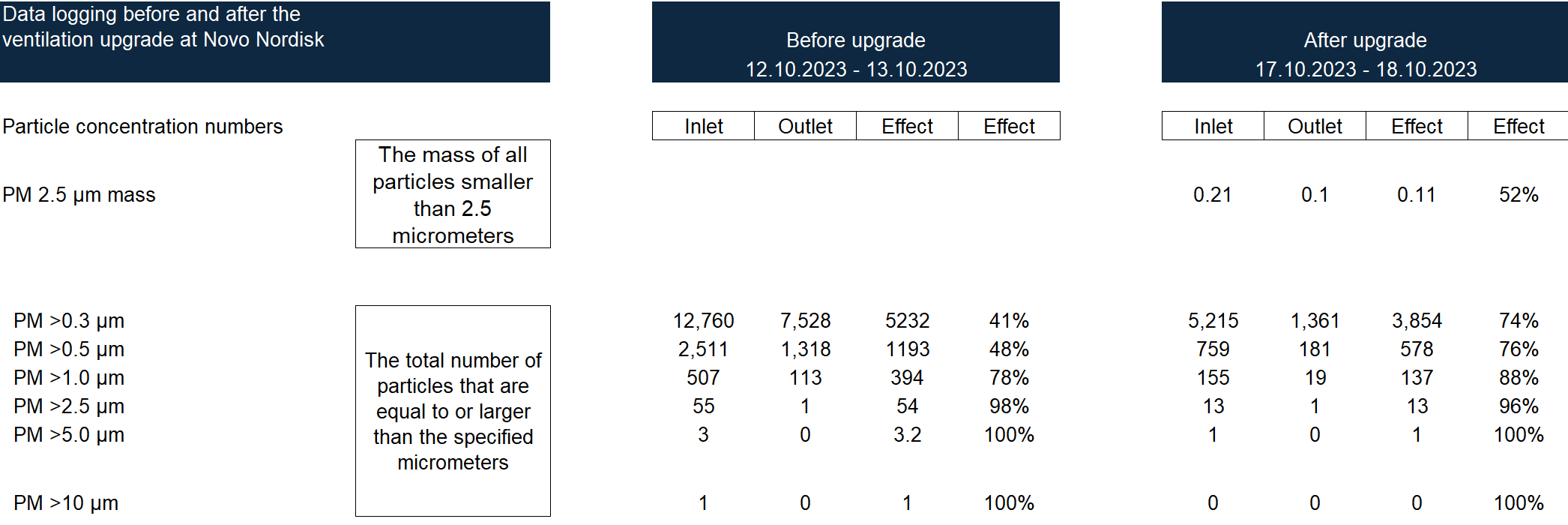

The documented results show a reduction in ultrafine particle admission, ranging from 74% to 96%. To ensure result accuracy, AeroTrack-calibrated sensor systems were installed before and after the ESP filter section as part of the Airzens filtration system installation.

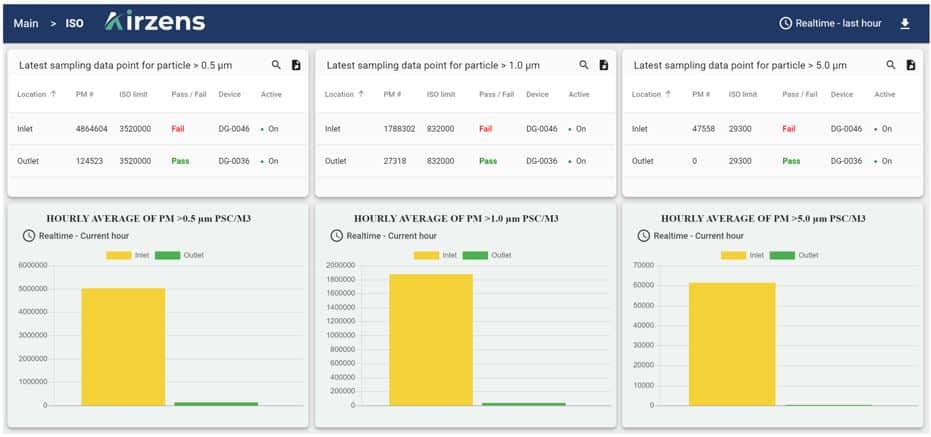

Furthermore, in line with ISO 8 cleanroom standards, the concentration of airborne particles larger than 0.3 µm per cubic meter of air is continuously monitored to meet the stringent control parameters set by Novo Nordisk.

Control parameters for Novo Nordisk;

The data demonstrates that, following the implementation of the Airzens filtration system, the particle quantity remains within ISO 8 cleanroom standards. Notably, there is a noticeable enhancement in filtration efficiency, particularly in the ultrafine spectrum (PM <2.5).

We conducted meticulous measurements of particle counts in the 0.3 to 5.0 µm range, categorized from “PM >0.3 µm” to “PM >5.0 µm.” Additionally, we measured the total particle mass at PM <2.5 µm.

The data below provides a comprehensive overview of the total particle count, both before and after the installation of Airzens technology. For PM >0.3 µm (as shown below), a conventional F7 bag filter removes 41% of particles larger than 0.3 µm, whereas an Airzens filter eliminates 74% of all particles larger than 0.3 µm.